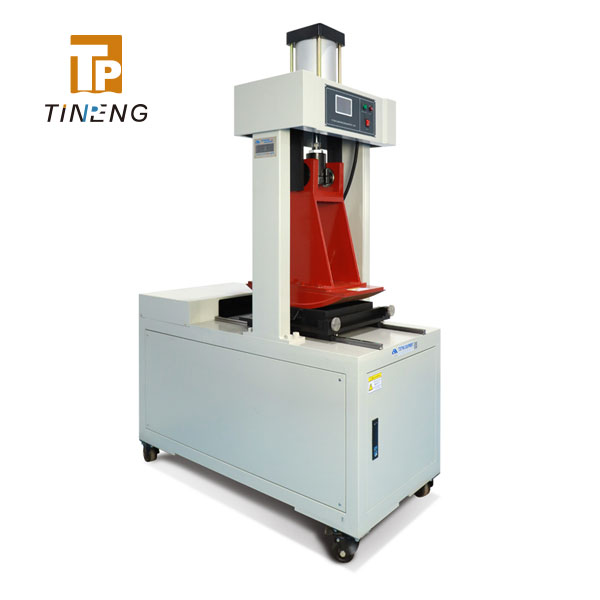

HTHY XY150

STANDARD

- EN 12697-10

- EN 12697-31

- ASTM D6925

- SHRP M-002

Get Wholesale Price

The Gyratory Compactor is built to SHRP specifications. It produces asphalt specimens that best predict long-term pavement performance. This information is not attainable from Marshall hammers or any other laboratory compaction equipment. Automatically measuring the specimen height during consolidation, produces a densification graph that the designer can use to produce the best possible paving mixture.

• Simple To Run

Pressing a single key lowers the ram, induces teh angle, performs compaction and records data. Every specimen is compacted with a constant consolidation pressure, angle and rate of gyration, which produces consistent samples time. The parameters are easily changed in minutes by following menu instructions.

• Operator Safety

The gyratory compactor is designed with the safety of the operator in mind. All rotating parts are beneath the work surface and away from the operator. Doors and access panels have safety switches for added protection from moving parts.

• Easy Installation

It is easy to install. Its compact size allows access through standard door openings.

• Quiet

Unlike other gyratory compactors and marshall hammers, this is quiet, allowing normal conversation in the area while the machine is running.

• Factory Calibrated, Ready to Run

This compactor comes calibrated and ready for use. The pressure, angle and rate of gyration are set to SHRP guidelines. No assembly or calibration is required. Simply connect to a power supply and you are ready to operate.

• Operation

The compactor can be programmed to operate automatically or the user can manually control each compaction step. The system can be programmed to compact specimens for a set number of gyrations or to desired specimen height. User can change the compaction angle.

• Display

It shows the number of gyrations, consolidation pressure and rate of gyration.

• Attached Extruder

A specimen extruder, which is provided, can be attached directly below the control panel. Its height can be adjusted to match that of the compactor tabletop, which allows the users to slide a mould with its compacted specimen directly into the extruder.

• Data Output

Output of speicimen height per gyration may be directed automatically to a printer or computer during the consolidation cycle. In addition, the stored data may be uploaded to a computer or printed after compaction is completed.

TECHNICAL PARAMETERS

Power: 380V

Vertical load: continuously adjustable from 200 to 1500 Kpa

Pressure accuracy: <±60 Kpa(for gyrations 1-5); <±18 Kpa(after fist 5 gyrations)

Number of gyratory: adjustable up to 999

External angle of gyration:Intemal angle to 1.16 to AASHTO T312/ ASTM D6925, adjustable to any other value between 0.7° and 1.4°.

Inside diameter of molds: 149.90mm to 150.00mm

Height of Mold cylinder: 230mm

Max Height of Specimen: 130mm

Gyratory compaction displacement range: 0-300 mm

Gyration rate: 30±0.5 cycles/min

Motor nominal speed: 1800 cycle/min

Dimension(HXWXD): 2140X890X940mm

Mould weight: 10.2 kg

Weight: 370 kg

Extruder for specimen removal from mould

One dia. 150mm mould

Height calibration block

Height filling block